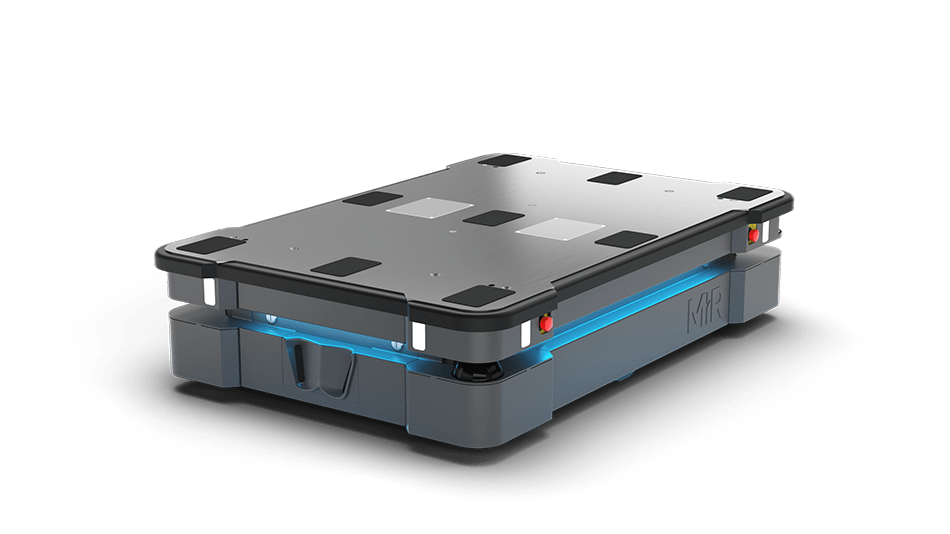

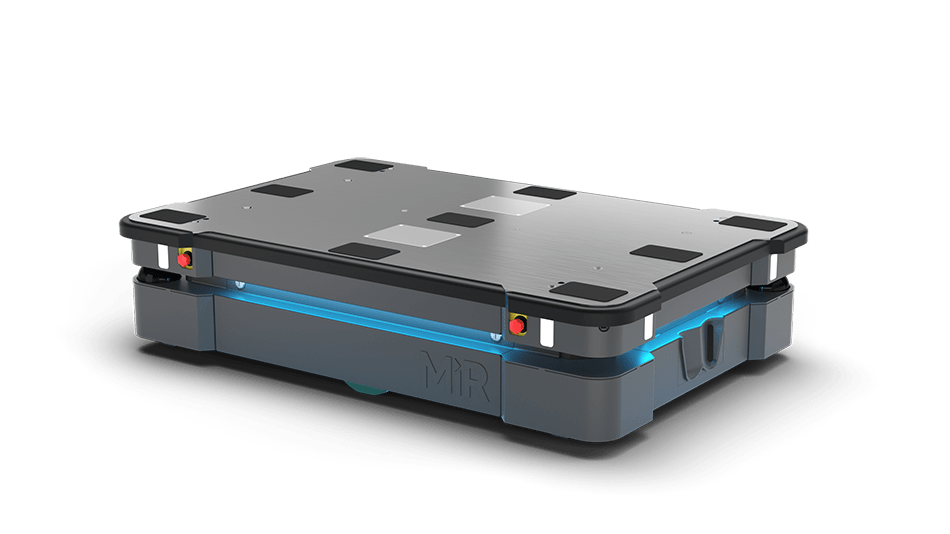

MiR600

Automate your internal transportation of heavy loads and pallets easily and cost-effectively

The MiR600 is a stronger and safer AMR. The MiR600 is compliant with the highest available robot standards making it superior to other AMRs on the market. With increased ability to withstand dust particles and fluids along with being compliant to the highest safety standards on the market, the MiR600 is safer, more stable and more reliable than other AMRs on the market.

Quick facts about the MiR600

2.0 m/s

8 hours

500 kg

1350 mm x 920 mm

Safe and efficient maneuvering

The collaborative MiR600 safely maneuvers around people and physical obstacles. With its advanced technology and sophisticated software, the robot autonomously navigates to find the most efficient path to its destination. When it meets obstacles, it will automatically re-route to avoid costly lags in logistics processes.

MiR600 is equipped with the latest laser-scanning technology that delivers a 360-degree visual for optimal safety. 3D cameras have a range of 30-2,000 mm above floor level to detect pallets.

Optimize pallet transportation without changing facility layout

With the MiR600 Pallet Lift, the MiR600 picks up, transports and unloads pallets autonomously, freeing up employees for more valuable tasks. There is no need to change the facility layout when operating the MiR600 as the function of wires, magnets or QR codes is replaced by sophisticated navigation software. Simply download CAD files of the facility to the robot or use its laser scanners to create a map – that’s all it takes to ensure a fast and cost-efficient implementation.

A robust robot for the industry

The MiR600 is the first IP52 rated AMR on the market together with MiRs other heavy duty robots, the very powerful MiR1350. With increased ability to withstand dust particles and fluids the mobile robot can be used in more environments, it can e.g. drive close to open gates or other places where it is exposed to waterdrops and dirt.

Highly user friendly and flexible

The user-friendly MiR600 gives you full control of the robot from the very start. MiR600 is controlled with the intuitive MiR Robot Interface via smartphone, tablet or PC, and can be programmed without any prior experience. The robot can also be integrated into your ERP system for a fully automated solution.

With the ability to quickly and easily integrate different top modules, the MiR600 can be equipped with pallet forks, conveyors, a robot arm or other options to support a wide range of applications.

| Designated use | Autonomous mobile robot (AMR) for internal transportation of heavy loads and pallets |

| Color | RAL 7011 / Iron Gray |

| Disclaimer | Specifications may vary based on local conditions and application setup |

| Length | 1 350 mm | 53.1 in |

| Width | 910 mm | 35.8 in |

| Height | 322 mm | 12.7 in |

| Weight | 243 kg | 536 lbs |

| Ground clearance | 27 mm | 1.0 in |

| Load surface | 1 304 x 864 mm | 51.3 x 34 in |

| Maximum payload | 600 kg | 1 322.8 lbs |

| Maximum speed | 2.0 m/s (7.2 km/h) | 6.6 ft/s (4.4 mph) |

| Operational corridor width for two robots passing | 4 950 mm | 194.9 in |

| Positioning accuracy (in controlled conditions) | Docking to VL-marker: ± 2 mm | 0.08 in on X-axis, ± 3 mm | 0.12 in on Y-axis, ± 0.25° yaw Moving to position: ± 100 mm | 3.94 in on X-axis, ± 83 mm | 3.27 in on Y-axis, ± 3.4° yaw |

| Traversable gap tolerance | Less than 30 mm | 1.18 in |

| Active operation time with maximum payload | up to 8.5 h |

| Active operation time with no payload | Up to 11 h |

| Standby time (robot is on and idle) | Up to 16 h |

| Maximum incline/decline | ± 3% at decreased speed |

| Battery type | Li-NMC, 47.7 V, 34.2 Ah |

| Charging ratio | Up to 1:12 (10 min charging gives 2 h runtime with maximum payload) |

| Charging current | Up to 35 A |

| Number of full charging cycles | Minimum 3 000 cycles |

| Environment | For indoor use only |

| Ambient temperature range, operation | 5–40°C | 41–104°F |

| Humidity | 10-85% non-condensing |

| IP Class | IP 52 |

| Floor conditions | No water, no oil, no dirt |

| EMC | EN61000-6-2, EN61000-6-4, (EN12895) |

| Safety standards for industrial vehicles | CE, EN1525, ANSI B56.5, ISO3691-4, RIA15.08, ISO13849-1 |

| Safety functions | 12 safety functions according to ISO 13849-1. The robot stops if a safety function is triggered. |

| WiFi | 2.4 GHz 802.11 g/n, 5 GHz 802.11 a/n/ac. |

| I/O connections | 4 digital inputs, 4 digital outputs, 1 Ethernet port with Modbus protocol |

| SICK safety laser scanners | 2 pcs, microScan3 (front and rear), give 360° visual protection around the robot |

| 3D cameras | 2 pcs, 3D camera Intel RealSense™ D435 FoV height: 1 800 mm | 70.9 in FoV distance in front of robot: 1 200 mm | 47.2 in FoV horizontal angle: 114° FoV minimum distance in front of robot for ground view: 250 mm | 9.8 in |

| Proximity sensors | 8 pcs |

| Audio | Speaker |

| Signal and status lights | Indicator lights on four sides, eight signal lights (two on each corner) |